Hi Jan, Geo & Jay

Development - Moire Coaster Set # 2

Moire Coaster : Top

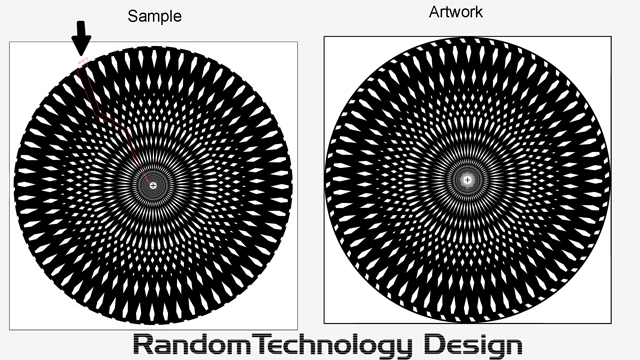

1 - Art work:

The factory improved the clear printed top

correctly separating the top from bottom art

however, they did not correctly fit the art within the cut diameter. It looks like maybe they cut the art

to the same original diameter 100mm whereas the art is set to 4" ( nearly 102mm).

Maybe they made a tool to cut the samples at 100mm but if so they do need to scale the art correctly.

Artwork center point

I noticed the two artworks are not correctly centered.

While I dont expect this to be perfect, some patterns require better centering.

To this end I've added center points in the artwork top and bottom to help the factory find the center.

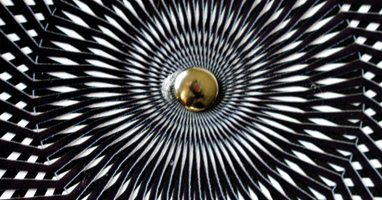

2 - Printing process:

My understanding of the printing process is based on this note from Geo and while I'm not a printing expert the explanation does not seem to match the sample.

email note:

"

Because clear film could not print black directly on the surface if not ,the black color will easy fall off and black color also not so black so factory need to print white color at bottom first ,and then add black color"

To me this means a white opaque color is printed first (which does adhere to the plastic) and black is printed over, on top of the white.

If this was correct (white printed first) we'd see white not black showing though

to the viewing side of the clear plastic.

If fact, the sample shows the exact opposite.

It looks like Black is printed first, then white on top

The result

correctly showing black showing through to the viewing side and white as

a second layer

seen from the back side as shown below.

Also, there is a linear texture that does not look like offset printing, but again...I'm no expert on this.

Please clarify...

Top Layer not lying flat:

1) Pls find out what this material is ?... just so I know.

New sample top thickness - .43mm

First sample top thickness - .36mm

My original sample thickness - .11mm thickness

While the new thicker .43mm material does lie more flat its not perfectly flat.

Going thicker may solve this problem but most sheet materials are produced, stored and sold as a roll

and have a natural curve.

My original samples are VERY thin at .11mm yet do not curve up at the edges

because I print them with the curve faceing down.

Has

has the factory tried simply printing so the curve is face down ? It seems like they are fighting against the nature of the material rather than working with it.

The textured print surface on the new sample is still face-down adding significant resistance to the turning movement. I suggested the factory find or construct a clear top layer has a smooth bottom surface and while

this was not done I may have found an easy solution to this.

Its the silicone release spray I've been requesting all along.

When I sprayed the backside

of the new sample (top layer) with silcone release the coaster movement was

immediately improved. It turns better, more smoothly, with little effort.

Pls confirm the factory can and will use this standard mold release, commonly available for the next samples

Moire Coaster : Bottom construction

1 - Material:

My samples are made from actual coasters, press board 102mm diameter with 1.5mm cork on the bottom

and art on top - total thickness aprox 4mm.

The new sample is aprox 2.5mm but just cork and artwork.

I'm concerned that the cork by itself it not rigid enough, warps very easily - Looks cheap and low quality.

While this coaster by design is less expensive than the original molded plastic coaster I feel

in this design

we are going too far in lower the quality.

I'd like to see and improvement here. Add the press board inner back into this design.

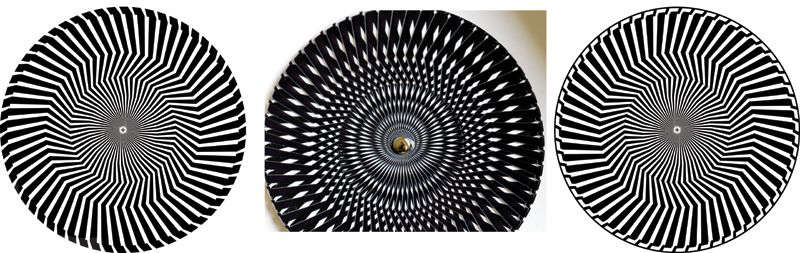

2 - Rivet:

I included samples of the smaller rivets with my last samples. Did you send these along to the factory?

Were they unable to find something similar in size The current sample uses a button type

rivet not much smaller in diameter and twice as tall - was .34mm now .85mm still a visual distraction and more likely a

problem for the bottom of a glass, cup or bottle.

|